1. Grinding wheel is turned around by hand as a mean to assures that free grinding wheel to base.

2. Position of basis arranged with distance 1-2mm from grinding wheel.

3. Position of switch is turned around by toward 1, grinding wheel will rotate.

Monday, February 15, 2010

Steps to turn on chisel grinding machine

Posted by Surya Angga Kesuma at 8:38 AM 0 comments

Sunday, January 31, 2010

Scraping process

Scraping process, which removes the remaining bits of bark and green growth from the bast and softens and spreads the fibers. To insure proper scraping, three different clam shells are used. Each shell has a different degree of courseness. The three types of clam shells are pipi, pae, and 'asi.

Posted by Surya Angga Kesuma at 9:57 AM 0 comments

Calculates rpm milling machine

n = ( Vc x 1000 ) / (phi x d )

n = ( Vc x 1000 ) / (phi x d )

Description :

- Vc = Velocity cutting

- 1000 = Coeficient factor

- phi = Constanta

- d = Cutter diameter

Posted by Surya Angga Kesuma at 9:27 AM 0 comments

Saturday, January 30, 2010

Calculates rpm turning machine

n = ( Vc x 1000 ) / (phi x d )

description :

Vc = Velocity cutting

1000 = Coeficient factor

phi = Constanta

d = Workpiece diameter

Posted by Surya Angga Kesuma at 9:58 PM 0 comments

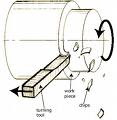

Turning process

Turning is a form of machining, a material removal process, which is used to create rotational parts by cutting away unwanted material. The turning process requires a turning machine or lathe, workpiece, fixture, and cutting tool. The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached to the turning machine, and allowed to rotate at high speeds. The cutter is typically a single-point cutting tool that is also secured in the machine, although some operations make use of multi-point tools. The cutting tool feeds into the rotating workpiece and cuts away material in the form of small chips to create the desired shape. Turning is used to produce rotational, typically axi-symmetric, parts that have many features, such as holes, grooves, threads, tapers, various diameter steps, and even contoured surfaces. Parts that are fabricated completely through turning often include components that are used in limited quantities, perhaps for prototypes, such as custom designed shafts and fasteners. Turning is also commonly used as a secondary process to add or refine features on parts that were manufactured using a different process. Due to the high tolerances and surface finishes that turning can offer, it is ideal for adding precision rotational features to a part whose basic shape has already been formed.

Turning is a form of machining, a material removal process, which is used to create rotational parts by cutting away unwanted material. The turning process requires a turning machine or lathe, workpiece, fixture, and cutting tool. The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached to the turning machine, and allowed to rotate at high speeds. The cutter is typically a single-point cutting tool that is also secured in the machine, although some operations make use of multi-point tools. The cutting tool feeds into the rotating workpiece and cuts away material in the form of small chips to create the desired shape. Turning is used to produce rotational, typically axi-symmetric, parts that have many features, such as holes, grooves, threads, tapers, various diameter steps, and even contoured surfaces. Parts that are fabricated completely through turning often include components that are used in limited quantities, perhaps for prototypes, such as custom designed shafts and fasteners. Turning is also commonly used as a secondary process to add or refine features on parts that were manufactured using a different process. Due to the high tolerances and surface finishes that turning can offer, it is ideal for adding precision rotational features to a part whose basic shape has already been formed.

Posted by Surya Angga Kesuma at 10:33 AM 0 comments

Cylindrical grinding process

The cylindrical grinder is a type of grinding machine used to shape the outside of an object. The cylindrical grinder can work on a variety of shapes however, the object must have a central axis of rotation. This includes but is not limited to such shapes as a cylinder, an ellipse, a cam, or a crankshaft.

The cylindrical grinder is a type of grinding machine used to shape the outside of an object. The cylindrical grinder can work on a variety of shapes however, the object must have a central axis of rotation. This includes but is not limited to such shapes as a cylinder, an ellipse, a cam, or a crankshaft.

Cylindrical Grinding is defined as having four essential actions

- The work (object) must be constantly rotating

- The grinding wheel must be constantly rotating

- The grinding wheel is fed towards and away from the work

- Either the work or the grinding wheel is traversed with the respect to the other.

Posted by Surya Angga Kesuma at 10:26 AM 0 comments

Surface grinding process

Surface Grinding is a manufacturing process which moves or grinding wheel relative a surface in a plane while a grinding wheel contacts the surface and removes a minute amount of material, such that a flat surface is created. The term “surface grinding” designates any process which accurately processes or grinds a surface.

Surface Grinding is a manufacturing process which moves or grinding wheel relative a surface in a plane while a grinding wheel contacts the surface and removes a minute amount of material, such that a flat surface is created. The term “surface grinding” designates any process which accurately processes or grinds a surface.

Surface grinding methods include: horizontal-spindle, vertical-spindle, vertical-spindle rotary grinding, horizontal spindle single disk, and vertical swivel head grinding.

Parts may require surface grinding for several reasons. The following are a few of the more common reasons:

- Produce a very flat surface.

- Very accurate thickness tolerance specified.

- A very smooth surface roughness Ra is specified/required.

- Cutting tool sharpening

Surface grinding machines and processes where first developed to to manufacture very tight tight tolerances, smooth surface finishes, and removing material from very hard materials .

Horizontal-spindle reciprocating table surface grinding | |||

Vertical-spindle rotary table surface grinding | |||

| |||

Posted by Surya Angga Kesuma at 10:02 AM 0 comments